OEM Linking Pin: 2015 Ford F-150 NVH Pads

- Posted on 19 April 2019

As part of the I-CAR Repairability Technical Support (RTS) OEM linking pin activity, we are helping to connect the collision repair industry to the vehicle makers. Recently we had a technical inquiry that asked about NVH pad replacement on aluminum Ford F-Series pickups.

Fuel Economy Technology Systems: Auto Start/Stop

- Posted on 17 April 2019

Tightening regulations on fuel economy along with rising awareness about pollution have influenced vehicle design and function in recent years. However, most consumers are not willing to sacrifice comfort, vehicle size, or power, so auto makers needed to use different methods to boost fuel economy. For the most part, aerodynamics can be directly related to fuel efficiency. The smoother air flows over the vehicle, the less power is required to make the vehicle move, leading to higher fuel economy. Unfortunately, a vehicle that has excellent aerodynamics may not be a functional vehicle for everyday consumers. So, other measures needed to be taken. In this series we’ll break down some of the methods used to boost aerodynamics and fuel economy along with any special cautions on how to repair them. Let’s check out the vehicle start/stop function.

General Motors: Spot-Weld Replacement

- Posted on 16 April 2019

There is sometimes confusion on how many spot welds to use when replacing body components. Sometimes you replace what you removed, sometimes you use more or less than what was removed. It all depends on the particular vehicle you are repairing and what the manufacturer requires to be done. Luckily General Motors (GM) has a good way of identifying how many welds to use to install the new part.

Nissan Tech News: March 2019

- Posted on 15 April 2019

An article in Nissan Tech News highlights different repair methods and procedures used in repairing Nissan vehicles. Nissan Sectioning Repair Tips article discusses reasons why a certain part may not be able to be sectioned, different welding methods, and ways to research and understand the body repair manual. Some reasons sectioning may be prohibited are due to material usage like ultra-high-strength steel (UHSS), panel layering/construction, or if the damage is in a crumple zone.

Sectioning and Partial Part Replacement: 2019 Audi A4 Allroad

- Posted on 12 April 2019

One of the top technical inquiries received at Ask I-CAR is, “Is there a sectioning or partial replacement procedure available?” To help answer this question, RTS has an OEM Partial Part Replacement Search available. Here you will find information on if these procedures are available on a specific vehicle. Let’s take a closer look at the 2019 Audi A4 Allroad.

Nissan Tech News Website Houses Valuable Information

- Posted on 11 April 2019

Did you know Nissan has a website that houses lots of useful information for collision repair technicians? Conveniently, this website is free to sign up for and once logged in, you have to access a wide variety of information on Nissan vehicles.

Toyota Collision Pros: Spring 2019

- Posted on 10 April 2019

Toyota has launched their Spring 2019 edition of Collision Pros. Some highlights in this issue that you may want to check out are the important details regarding pre- and post-repair checklists, and Toyota Technical Information Systems (TIS).

Powertrain Overview: Plug-In Hybrid Electric Vehicle (PHEV)

- Posted on 09 April 2019

Since the creation of the first modern automobile nearly a century and a half ago, there has been one dominant engine option on the market, the gasoline internal combustion engine. Now the gasoline internal combustion engine has some challengers trying to steal the crown. There have been many different types of engines in the past but many of them relied solely on fossil fuels to operate.

Backup Batteries and Main Battery Disconnect

- Posted on 09 April 2019

Backup batteries sometimes referred to as auxiliary or supplemental batteries, serve an important role in maintaining power for certain vehicle systems even while the 12-volt battery power is cut. The backup batteries can aid in emergency situations by maintaining power for features like GM OnStar, Toyota Safety Connect System, and FCA Assist to name a few.

Bumper Cover Repair With ADAS: Volkswagen

- Posted on 05 April 2019

A simple bumper repair on a modern vehicle may not be as simple as it seems. New technologies like blind spot monitoring, adaptive cruise control, and other advanced driver assistance systems (ADAS) utilize sensors behind the bumper covers. The ability for these sensors to be able to see clearly, normally requires special caution when considering a bumper repair. Many OEMs have different levels of warnings when it comes to repairing bumper covers with ADAS. So, what does Volkswagen say on the subject?

Selecting The Correct Welding Equipment

- Posted on 04 April 2019

In case you missed it, RTS issued several different articles outlining some features and variables to consider when purchasing welding equipment. When it comes to selecting your next piece of welding equipment, there are many different choices.

Active Suspension for Road Handling

- Posted on 03 April 2019

Suspension systems are made to absorb most of the impact of a bump in the road. This ultimately increases the ride quality from inside the vehicle. Over time, suspension has greatly improved. There are several different types of suspension, including active suspension.

Back-To-Basics: Door Intrusion Beams

- Posted on 02 April 2019

Sometimes, going back to the basics can make the difference between a quality repair and a failed repair. When it comes to a damaged door intrusion beam, here are some things to consider.

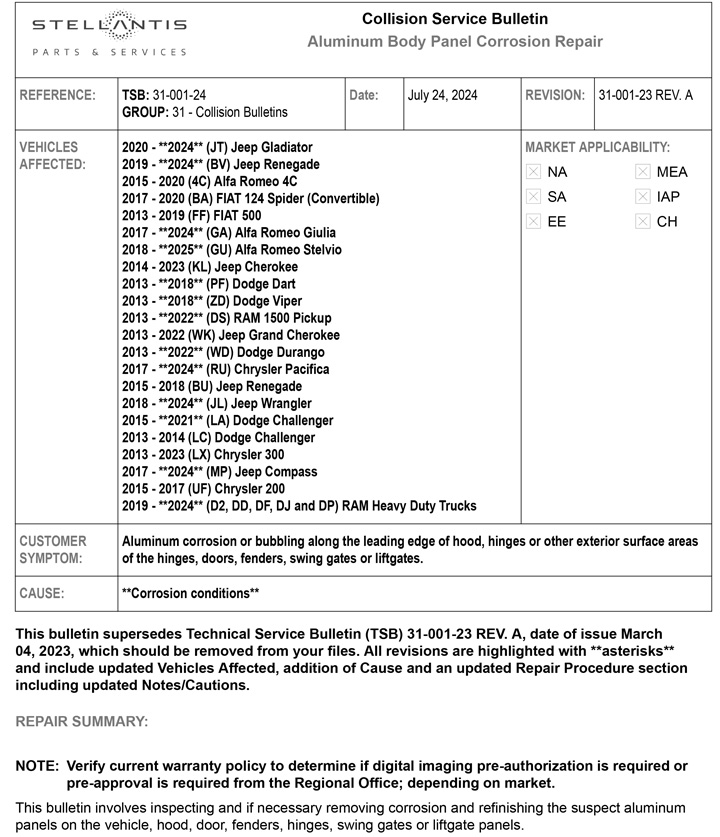

FCA/Stellantis: Aluminum Body Panel Corrosion Repair

- Posted on 01 April 2019

Weight-saving aluminum is being used more and more on vehicles to aid in fuel economy. There has been a learning curve for collision technicians to be able to adapt to repairing aluminum. Also, with aluminum comes a form of oxidation that typically appears near the panel flanges. FCA/Stellantis addresses this issue and how to fix it in a recently released Collision Bulletin.

Sectioning and Partial Part Replacement: 2019 Ford F-150

- Posted on 29 March 2019

One of the top technical inquiries received at Ask I-CAR is, “Is there a sectioning or partial replacement procedure available?” To help answer this question, RTS has an OEM Partial Part Replacement Search available. Here you will find information on if these procedures are available on a specific vehicle. Let’s take a closer look at the 2019 Ford F-150.

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

BMW Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Friday, 10 April 2020

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

Battery Backup And Low-Voltage Disconnect: Toyota/Lexus

Thursday, 22 January 2026

When an accident happens, how will you call for help? Maybe the telematics system, equipped with a backup battery, could automatically do this, even if the main power is cut off. What are the repair...

-

Your 2025 Favorites: Top 20 Sectioning and Partial Part Vehicles

Wednesday, 21 January 2026

Now that the new year is underway, let’s take a look at your 2025 favorite vehicles in the OEM Partial Part Replacement Search.

-

I-CAR Repairers Realm: New In 2026: I-CAR Academy - Coming Soon

Tuesday, 20 January 2026

I-CAR is having a discussion on I-CAR Academy.

-

Your 2025 Favorites: Top Articles

Friday, 16 January 2026

As 2026 rolls in, we can reflect back on what the previous year had to offer. Let's take a look at some of the collision industry information you've been most interested in from this past year....

-

App-Based Connected Services Considerations: Toyota/Lexus

Thursday, 15 January 2026

Have you had the experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and may...

-

Digital Key Considerations: Toyota/Lexus

Thursday, 15 January 2026

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

-

Nissan/INFINITI Position Statements: Advanced Driver Assistance System Components

Thursday, 8 January 2026

Nissan/INFINITI released position statements on the use of salvaged, aftermarket, and "secondary-market" advanced driver assistance systems (ADAS) components.

-

I-CAR Repairers Realm: RTS 2025 Year In Review - Now Available

Tuesday, 6 January 2026

I-CAR had a discussion on the Repairability Technical Support (RTS) 2025 year in review.

-

Ford On Target 2025: Volume 4

Monday, 5 January 2026

Ford has released the fourth installment of their On Target publication for 2025.

-

Structural Sectioning Procedures: Ford/Lincoln - UPDATE

Friday, 19 December 2025

Ask I-CAR receives many technical inquiries referring to sectioning. The collision repair industry wants to know where can you section, does the OEM have a sectioning procedure, and where can I find the...

- 2026

- January 2026 (9)

- 2025

- December 2025 (8)

- November 2025 (11)

- October 2025 (13)

- September 2025 (11)

- August 2025 (12)

- July 2025 (11)

- June 2025 (11)

- May 2025 (11)

- April 2025 (13)

- March 2025 (12)

- February 2025 (11)

- January 2025 (12)

- 2024

- December 2024 (8)

- November 2024 (10)

- October 2024 (13)

- September 2024 (10)

- August 2024 (12)

- July 2024 (11)

- June 2024 (9)

- May 2024 (13)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (9)

- 2023

- December 2023 (8)

- November 2023 (12)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (11)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (11)

- October 2021 (13)

- September 2021 (14)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (11)

- April 2021 (14)

- March 2021 (20)

- February 2021 (14)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (14)

- May 2020 (14)

- April 2020 (19)

- March 2020 (12)

- February 2020 (13)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (19)

- April 2019 (20)

- March 2019 (20)

- February 2019 (18)

- January 2019 (17)

- 2018

- December 2018 (18)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (17)

- April 2018 (19)

- March 2018 (21)

- February 2018 (15)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (19)

- July 2017 (18)

- June 2017 (19)

- May 2017 (18)

- April 2017 (13)

- March 2017 (18)

- February 2017 (10)

- January 2017 (11)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (10)

- August 2016 (11)

- July 2016 (8)

- June 2016 (10)

- May 2016 (5)

- April 2016 (11)

- March 2016 (12)

- February 2016 (10)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (6)

- October 2015 (8)

- September 2015 (7)

- August 2015 (11)

- July 2015 (7)

- June 2015 (5)

- May 2015 (7)

- April 2015 (8)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (12)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (26)