I-CAR 360: 2019 Kia Optima Video Now Available

- Posted on 14 October 2019

The I-CAR Repairability Technical Support (RTS) team recently developed a new I-CAR 360 video on the 2019 Kia Optima. The video provides a 360° tour around the Optima. Let’s take a look.

What’s In A Steering Column: Heated Steering Wheel

- Posted on 11 October 2019

As vehicles are becoming more advanced, we are finding technology where it never was before. Sometimes it is in plain sight, such as infotainment systems, GPS, and a head-up display. However, sometimes it is concealed in places one may not expect.

Requirements And Considerations For Achieving An Accurate Advanced Driver Assistance System (ADAS) Calibration

- Posted on 11 October 2019

It is no secret that more of today’s vehicles are equipped with at least one advanced driver assistance system (ADAS), with many of the newer models having ADAS as standard equipment. This only increases the importance of making sure accurate ADAS calibration is performed after a collision.

ADAS Courses Added To The Calibration Hotspot Article

- Posted on 09 October 2019

As you may know, there are many advanced driver assistance systems (ADAS) inputs (cameras/sensors) that need calibration/programming during or after the repair process. This is why it is important to learn about these different cameras/sensors, where they are often located, and how they work. The RTS team has compiled a list of articles proven to be helpful when dealing with ADAS, calibration, and scanning.

Honda/Acura: Body Repair Manual Welding & Sectioning Guideline Revisions - UPDATE

- Posted on 08 October 2019

Honda/Acura has published updated Body Repair News bulletins on welding and sectioning.

Advanced Driver Assistance Systems: 2019 Hyundai Kona

- Posted on 07 October 2019

While many have noticed that advanced driver assistance systems (ADAS) are showing up on vehicles, there still is confusion on what is required of these systems after a collision occurs. The Ask I-CAR team frequently gets questions in regard to calibration of ADAS. Many of these questions can be answered simply by using the OEM Calibration Requirements Search. However, there are some questions that may need more details than the calibration search provides. Let’s take a look at the 2019 Hyundai Kona ADAS.

Ford/Lincoln Fixed Glass Replacement With Adhesive Moldings

- Posted on 07 October 2019

Ford recently updated the information on their fixed glass procedures in regard to fixed glass with adhesive moldings.

Previously, the Ford On Target: 2019 Volume 2 stated that any stationary glass with adhesive moldings must be discarded, and a new glass installed. Ford has revised the Ford On Target 2019: Volume 2 with new information on replacing fixed glass with adhesive moldings. It now states:

Diagnostic Trouble Codes (DTCs): Don't Just Clear Codes

- Posted on 04 October 2019

As collision repair technicians, our expertise is not typically scanning and diagnostics related. However, the influx of technology, electrical components, and sensors into vehicles will require technicians to acquire a basic knowledge of scanning and diagnostics. A lot of information is provided from a scan tool, but what do we do with this information?

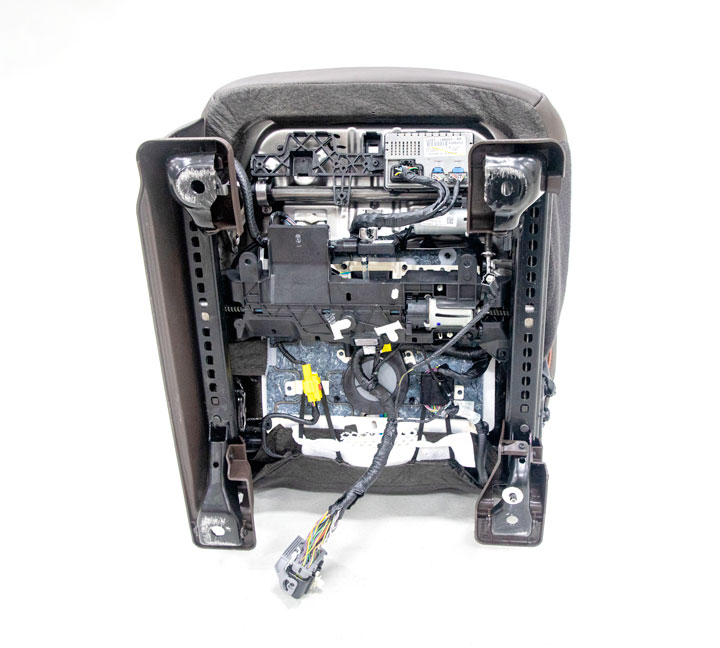

What’s In A Seat: Haptic Feedback

- Posted on 03 October 2019

As vehicles are becoming more advanced, we are finding technology where it never was before. Sometimes it is in plain sight, such as infotainment systems, GPS, and head-up display. However, sometimes it is concealed in places one may not expect.

Advanced Driver Assistance Systems: 2019 Kia Sportage

- Posted on 02 October 2019

While many have noticed that advanced driver assistance systems (ADAS) are showing up on vehicles, there still is confusion on what is required of these systems after a collision occurs. The Ask I-CAR team frequently gets questions in regard to calibration of ADAS. Many of these questions can be answered simply by searching the OEM Calibration Requirements Search. However, there are some questions that may need more details than the calibration search provides. Let’s take a look at the 2019 Kia Sportage ADAS.

Back-To-Basics: Broken Wires

- Posted on 01 October 2019

Sometimes, going back to the basics can make the difference between a quality repair and a failed repair. Thousands of feet of wire is used in modern vehicles. Driven by consumer demand for more tech features, along with the incorporation of advanced driver assistance systems (ADAS), we won’t likely be turning back on the amount of wire used. With all of that wire, some organization is needed to keep things straight. Wires headed to the same destinations are bundled into wire harnesses. While this is great for keeping all these wires under control, it can make it difficult to find an electrical problem after a collision.

Repairer Driven News: 2020 Honda CR-V

- Posted on 30 September 2019

Repairer Driven News (RDN) released an article on the changes to the 2020 CR-V. The Honda CR-V now comes standard with Honda Sensing for all trim packages.

Repairer Driven News: 2020 Land Rover Defender

- Posted on 27 September 2019

Repairer driven news (RDN) released an article on the changes to the 2020 Land Rover Defender. This Defender is no longer a body over frame design. In fact, the structure of this vehicle is unlike any other Land Rover model with its own new platform. The “purpose-engineered” D7x platform was built to be the stiffest structure Land Rover has ever made. The body of this vehicle is aluminum intensive and lightweight.

Back-To-Basics: Painted Grounds

- Posted on 26 September 2019

Sometimes, going back to the basics can make the difference between a quality repair and a failed repair. Electrical circuits are nothing new in the collision industry. Vehicle circuits primarily use 12 V direct current (DC) for electricity, which requires every circuit to have a good ground in order to be closed. The more advanced vehicle electrical systems become, the more need there is for additional grounds.

OEM Linking Pin: Refinishing Park Assist Sensors - FCA/Stellantis

- Posted on 25 September 2019

As part of the I-CAR Repairability Technical Support (RTS) OEM linking pin activity, we are helping to connect the collision repair industry to the vehicle makers. Recently we had a technical inquiry that asked if FCA/Stellantis allows park assist sensors to be refinished.

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

BMW Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Friday, 10 April 2020

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

SEMA 2025: EV Collision Solutions

Thursday, 5 March 2026

I-CAR had numerous presentations at the 2025 SEMA show. One of the presentations focuses on Midtronics high-voltage (HV) safety solutions.

-

I-CAR Repairers Realm: FCA/Stellantis Corrosion Protection Updates - Coming Soon

Wednesday, 4 March 2026

I-CAR is having a discussion on FCA/Stellantis corrosion protection updates.

-

Bumper Cover Repair With ADAS: Mazda - UPDATE

Tuesday, 3 March 2026

A simple bumper repair on a modern vehicle may not be as simple as it seems. New technologies like blind spot monitoring, adaptive cruise control, and other advanced driver assistance systems (ADAS)...

-

I-CAR Just In Time: Torque Wrench Use

Friday, 27 February 2026

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

-

I-CAR Repairers Realm: I-CAR Registered Apprenticeship Program - Now Available

Thursday, 26 February 2026

I-CAR had a discussion on the I-CAR Registered Apprentice Program (RAP).

-

Bumper Cover Repair With ADAS: FCA/Stellantis

Wednesday, 25 February 2026

A simple bumper repair on a modern vehicle may not be as simple as it seems. New technologies like blind spot monitoring, adaptive cruise control, and other advanced driver assistance systems (ADAS)...

-

I-CAR Just In Time: Digital Tram Gauge Basics And Steering Column Measurement Tips

Thursday, 19 February 2026

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

-

GM Repair Insights: Fall 2025

Tuesday, 17 February 2026

The fall edition of General Motors (GM) Repair Insights magazine is now available.

-

GM Repair Insights: Winter 2026

Tuesday, 17 February 2026

The winter edition of General Motors (GM) Repair Insights magazine is now available.

-

SEMA 2025: Three-Dimensional Measuring Presentations

Thursday, 12 February 2026

I-CAR had numerous presentations at the 2025 SEMA show. Two presentations featured information about three-dimensional measuring of vehicles.

- 2026

- March 2026 (3)

- February 2026 (11)

- January 2026 (11)

- 2025

- December 2025 (8)

- November 2025 (11)

- October 2025 (13)

- September 2025 (11)

- August 2025 (12)

- July 2025 (11)

- June 2025 (11)

- May 2025 (11)

- April 2025 (13)

- March 2025 (12)

- February 2025 (11)

- January 2025 (12)

- 2024

- December 2024 (8)

- November 2024 (10)

- October 2024 (13)

- September 2024 (10)

- August 2024 (12)

- July 2024 (11)

- June 2024 (9)

- May 2024 (13)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (9)

- 2023

- December 2023 (8)

- November 2023 (12)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (11)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (11)

- October 2021 (13)

- September 2021 (14)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (11)

- April 2021 (14)

- March 2021 (20)

- February 2021 (14)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (14)

- May 2020 (14)

- April 2020 (19)

- March 2020 (12)

- February 2020 (13)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (22)

- June 2019 (20)

- May 2019 (19)

- April 2019 (20)

- March 2019 (20)

- February 2019 (18)

- January 2019 (17)

- 2018

- December 2018 (18)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (16)

- April 2018 (19)

- March 2018 (21)

- February 2018 (15)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (19)

- July 2017 (18)

- June 2017 (19)

- May 2017 (18)

- April 2017 (13)

- March 2017 (18)

- February 2017 (10)

- January 2017 (11)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (10)

- August 2016 (11)

- July 2016 (8)

- June 2016 (10)

- May 2016 (5)

- April 2016 (11)

- March 2016 (12)

- February 2016 (10)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (6)

- October 2015 (8)

- September 2015 (7)

- August 2015 (11)

- July 2015 (7)

- June 2015 (5)

- May 2015 (7)

- April 2015 (8)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (12)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (26)