OSHA Hazard Communication Standard Revision

The Occupational Safety and Health Administration (OSHA) is requiring that all employees be trained, by December 1st of 2013, on the revision to its Hazard Communication Standard. The revision to the 1994 standard more closely aligns with the Globally Harmonized System (GHS), an international approach to labeling and classifying hazardous products.

Why the change? Credit the global marketplace. The U.S. is both a major importer and exporter of chemicals. American workers often see labels and material safety data sheets (MSDS) from the U.S. and from other countries. The diverse and sometimes conflicting national and international requirements can create confusion among those who seek to use hazardous material information effectively.

Major Changes

The Hazard Communication Standard regulates identification and communication of hazardous products in the workplace. The major changes include:

- Hazard classification: There are now specific criteria for classification of health and physical hazards, to help ensure that evaluations of hazardous effects are consistent across product makers.

- Labels: Chemical manufacturers and importers will be required to provide a label that includes the product name, supplier identification including an emergency phone number, the word "Warning" or "Danger," pictograms, and hazard statements for each hazard class and category. Precautionary statements must also be provided.

Safety Data Sheets: The word "Material" has been dropped, and there is a specified 16-section format. The previous standard had a nine-section material safety data sheet, but product makers could generally deviate from that as long as the information was there. Now all safety data sheets will be 16 sections.

If manufacturers, importers, distributors, or employers become newly aware of any significant information regarding the hazards of a chemical, the label should be revised to the new standard within six months of becoming aware of the new information. With products that have not changed, product makers have between June and December of 2015 to convert their labels and safety data sheets to the new standard.

Why the December 1st 2013 training requirement for employees if the product makers have until 2015 to implement the new standard requirements? OSHA believes that American workplaces will soon begin to receive labels and SDSs that are consistent with the GHS, since many American and foreign chemical manufacturers have already begun to produce GHS-compliant labels and SDSs. It's important to ensure that when employees begin to see the new labels and SDSs in their workplaces, they will be familiar with them, understand how to use them, and be able to access the information effectively.

Label Requirements

The supplier must provide at least the following on every hazardous material label:

- The product identifier (name)

- A signal word, indicating the relative level of severity of the hazard, either "Danger" (more severe) or "Warning" (less severe)

- Hazard statements assigned to each applicable hazard class or category, such as "Flammable" or "Carcinogen"

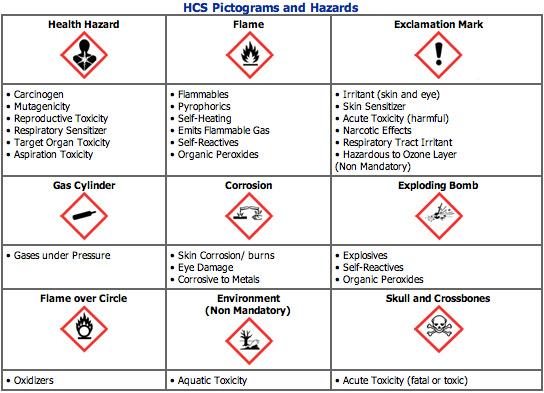

- Pictograms, eight to choose from and one environmental hazard option

- Precautionary statements stating what should be done to protect the worker from the hazard, such as "Respiratory protection required" or "Keep away from open flame"

- Name, address, and telephone number of the product maker or importer or other responsible party

The eight pictograms are shown below.

One or more of these pictograms must be on supplier labels.

One or more of these pictograms must be on supplier labels.

Note that the pictograms are all within a red diamond. There are two new pictograms, one indicating "Health Hazard" and one indicating "Explosive." Health Hazards include carcinogens, reproductive toxins, and other toxins that target a specific organ. Explosives have been separated from flammables. The Environment pictogram is non-mandatory, as OSHA does not oversee environmental hazards.

Workplace Labels

Workplace labels are mentioned in the revised standard, but nothing has really changed. The minimum requirements for a workplace label are still the product name and indications on the specific hazards of the product, using pictograms, phrases, or words, whatever is available and applicable. If pictograms and phrases are used, they should be consistent with the revised standard. Sources for the label can be as complicated as using labeling kits from a safety catalog, or as simple as writing the information directly and legibly on the container in permanent marker.

National Fire Protection Association (NFPA) labels, with the diamond shape and the color and numbering system, can be used as workplace labels, but there's an important difference in the numbering system used by the NFPA compared to the GHS. With the NFPA system, the higher the number the greater the hazard, so a "1" is the least severe hazard. With the GHS, it's just the opposite, the lower the number the more severe the hazard, so a "1" is the most severe hazard. When using the NFPA label as a workplace label, use the GHS numbering system. The numbers are often included in the SDS.

Safety Data Sheet (SDS)

The information required on the SDS remains essentially the same as that in the 1994 standard, except that the information must be presented using 16 specific headings in a specified sequence.

The format of the 16-section SDS should include the following sections:

- Section 1. Identification

- Section 2. Hazard(s) identification

- Section 3. Composition/information on ingredients

- Section 4. First-Aid measures

- Section 5. Fire-fighting measures

- Section 6. Accidental release measures

- Section 7. Handling and storage

- Section 8. Exposure controls/personal protection

- Section 9. Physical and chemical properties

- Section 10. Stability and reactivity

- Section 11. Toxicological information

- Section 12. Ecological information

- Section 13. Disposal considerations

- Section 14. Transport information

- Section 15. Regulatory information

- Section 16. Other information, including date of preparation or last revision

Note that although the headings for Sections “12” “15” are mandatory, OSHA will not enforce the content of these four sections because these sections are within other agencies' jurisdictions.

Employer's Responsibility

Repair facility owners and managers need to become familiar with the standard revisions and train their employees on recognizing the new labels and reading the new SDS versions by December 1st.

OSHA has some downloadable "quick cards" available for help with this training. Go to www.osha.gov.

Besides the general information, it's even more important that repair facility owners and managers explain how the hazardous communication procedures will change in the specific facility. If OSHA makes a visit, that is what they will be looking for; if employees know how to find and read the information on hazardous materials that they work with.

Conclusion

OSHA recently updated its Hazard Communication Standard, which covers requirements for labels, safety data sheets, and hazard material classifications. Several product makers have already begun using the new labeling and SDS system, so, OSHA is requiring employees be trained to recognize the new label and SDS format by December 1st, 2013.

Even more important than general information is for shop owners and managers to inform employees about how hazard communications will change in the repair facility.

Related I-CAR Courses

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

BMW Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Friday, 10 April 2020

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

Structural Sectioning Procedures: Ford/Lincoln - UPDATE

Friday, 19 December 2025

Ask I-CAR receives many technical inquiries referring to sectioning. The collision repair industry wants to know where can you section, does the OEM have a sectioning procedure, and where can I find the...

-

Body Repair Manual Symbols: Hyundai

Wednesday, 17 December 2025

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

-

Body Repair Manual Symbols: Genesis

Wednesday, 17 December 2025

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

-

App-Based Connected Services Considerations: BMW

Wednesday, 10 December 2025

Have you had an experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and...

-

Digital Key Considerations: BMW

Wednesday, 10 December 2025

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

-

Mercedes-Benz Vehicles On The RTS OEM Calibration Requirements Search

Thursday, 4 December 2025

Mercedes-Benz models are now listed in the OEM Calibration Requirements Search page on the RTS website. You're going to notice a difference between other vehicle search results and Mercedes-Benz...

-

I-CAR Repairers Realm - New In 2026: Mixed Attachment Methods And Steel Sectioning Recertification - Now Available

Monday, 1 December 2025

I-CAR had a discussion on the new Mixed Attachment Methods course launching in 2026.

-

Repairer Driven News: SCRS OEM Collision Repair Technology Summit Sessions

Monday, 1 December 2025

Repairer Driven News published three articles highlighting safety inspection topics that took place during the Collision Repair Specialists (SCRS) OEM Collision Repair Technology Summit at the 2025...

-

I-CAR Audi Collision Repair And Electromechanical Repair Overview Courses

Tuesday, 25 November 2025

I-CAR has developed courses that provide an overview of collision repair and electromechanical repair for current Audi vehicles.

-

SEMA 2025: Ford/Lincoln Presentations

Monday, 24 November 2025

I-CAR had numerous presentations at the 2025 SEMA show. Ford/Lincoln delivered two presentations.

- 2025

- December 2025 (8)

- November 2025 (11)

- October 2025 (13)

- September 2025 (11)

- August 2025 (12)

- July 2025 (11)

- June 2025 (11)

- May 2025 (11)

- April 2025 (13)

- March 2025 (12)

- February 2025 (11)

- January 2025 (12)

- 2024

- December 2024 (8)

- November 2024 (10)

- October 2024 (13)

- September 2024 (10)

- August 2024 (12)

- July 2024 (11)

- June 2024 (9)

- May 2024 (13)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (9)

- 2023

- December 2023 (8)

- November 2023 (12)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (11)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (11)

- October 2021 (13)

- September 2021 (14)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (11)

- April 2021 (14)

- March 2021 (20)

- February 2021 (14)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (14)

- May 2020 (14)

- April 2020 (19)

- March 2020 (12)

- February 2020 (13)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (19)

- April 2019 (20)

- March 2019 (20)

- February 2019 (18)

- January 2019 (17)

- 2018

- December 2018 (18)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (17)

- April 2018 (19)

- March 2018 (21)

- February 2018 (15)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (19)

- July 2017 (18)

- June 2017 (19)

- May 2017 (18)

- April 2017 (13)

- March 2017 (18)

- February 2017 (10)

- January 2017 (11)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (10)

- August 2016 (11)

- July 2016 (8)

- June 2016 (10)

- May 2016 (5)

- April 2016 (11)

- March 2016 (12)

- February 2016 (10)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (6)

- October 2015 (8)

- September 2015 (7)

- August 2015 (11)

- July 2015 (7)

- June 2015 (5)

- May 2015 (7)

- April 2015 (8)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (12)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (26)