Top 10 Cars of 2014

- Posted on 06 January 2015

Can you guess who tops the list of cars sold in America in 2014? These are the vehicles that are on the road and potentially in your collision repair facility.

Can you guess who tops the list of cars sold in America in 2014? These are the vehicles that are on the road and potentially in your collision repair facility.

To Wrap-up 2014 Collision Hub put together a video of there favorite things from 2014. There are some highlights on different tools and equipment.

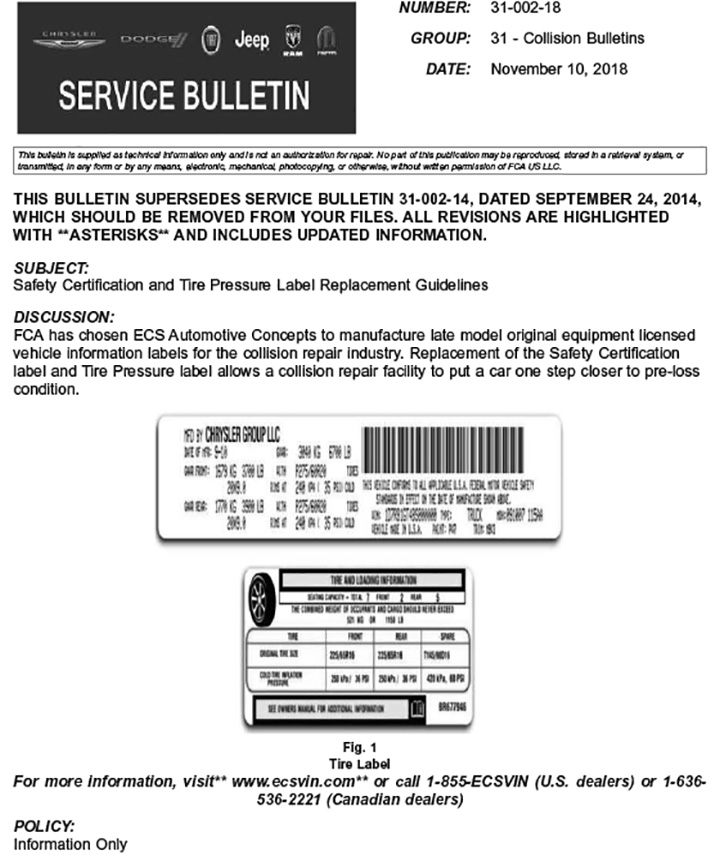

We've added the Safety Certification and Tire Pressure Label Replacement Guidelines Collision Bulletin from FCA/Stellantis that addresses safety certification and tire pressure label replacement guidelines.

Having a problem getting your replacement Kia Optima bumper cover to fit properly? Wondering if maybe you got the wrong part?

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts, but Chrysler, Dodge, Jeep, and RAM keep it pretty basic.

The ninth column in the OEM Technical Information Matrix is pretty straight forward: Corrosion Protection Methods and Materials. Most OEMs have information on anti-corrosion materials and application equipment including a list of approved materials and part numbers.

Ever hear the quote: "if you do what you've always done, you'll get what you've always gotten"? When it comes to collision repairs, it's far from accurate.

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts. All of the different names can be confusing, especially when repairing a variety of vehicle makes and models. Thankfully, General Motors (GM) uses terms that most of us are familiar with.

This article originally appeared in the November/December edition of Fixed Ops Magazine.

Collision repair professionals are no different than any other professional – we are resistant to change. It took many years for repairers to make the switch to “MIG welding” for welding early unibody vehicles. (For this article we’ll use the term gas metal arc welding (GMAW) metal inert gas (MIG), or GMA (MIG)). (More on the reason, later.) It was a technology that was unfamiliar to many and there wasn’t a perceived need for change. History would prove otherwise, as there may not be a collision repair business in the country that doesn’t have a GMA (MIG) welder.

When you visit the Audi OEM Information page on the RTS website, you will see a new icon for videos.

With the latest addition of the OEM Hybrid And Electric Vehicle Disable Search to the RTS portal, we have also added a new icon to the OEM Information pages to help you with quicker access.

A new search function is now avaialbe on the I-CAR Repairability Technical Support (RTS) Portal and we're calling it the OEM Hybrid and Electric Vehicle Disable Search

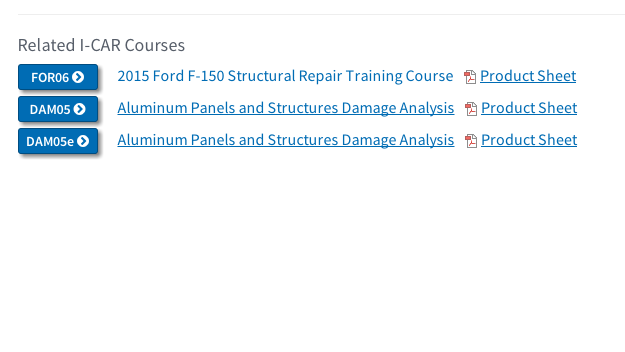

We've added a new feature to the RTS Portal to help you get more of the information that you are searching for through I-CAR training courses.

On November 11, 2014, Ford announced that the 2015 Ford F-150 production has begun for delivery this month. It's been a month, have you seen one yet?

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts. All of the different names can be confusing, especially when repairing a variety of vehicle makes and models.

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

As 2026 rolls in, we can reflect back on what the previous year had to offer. Let's take a look at some of the collision industry information you've been most interested in from this past year....

Have you had the experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and may...

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

Nissan/INFINITI released position statements on the use of salvaged, aftermarket, and "secondary-market" advanced driver assistance systems (ADAS) components.

I-CAR had a discussion on the Repairability Technical Support (RTS) 2025 year in review.

Ford has released the fourth installment of their On Target publication for 2025.

Ask I-CAR receives many technical inquiries referring to sectioning. The collision repair industry wants to know where can you section, does the OEM have a sectioning procedure, and where can I find the...

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

Have you had an experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and...