General Motors eAssist Electric System

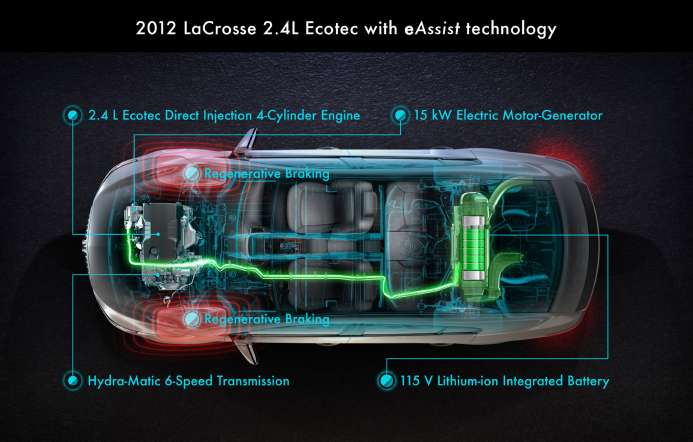

Figure 1 - This is the eAssist system on the 2012 Buick LaCrosse.

Figure 1 - This is the eAssist system on the 2012 Buick LaCrosse. Another version of electric-assist vehicle technology is showing up in collision repair facilities. General Motors in 2012 introduced what it refers to as "light electrification" technology on select models. This system is called eAssist, and is available on some 2012 Buick LaCrosse, Regal, and 2013 Chevrolet Malibu models (see Figure 1).

The eAssist system is a similar configuration to the Belt Alternator Starter (BAS) system that was available on some recent model year GM vehicles. The BAS system was discontinued as of the 2010 model year.

System Features

The eAssist system uses a starter/generator, which may also be referred to as the drive motor. This unit serves as an AC generator, a power assist to the engine in certain driving situations, and for starting the engine when it is in the auto-stop mode.

The drive motor is mounted to the front of the engine in place of the alternator. The drive motor is connected to the crankshaft pulley using a specially designed serpentine belt and belt tensioner.

Vehicles with the eAssist system also have regenerative braking, electronically controlled shutters in the lower grille, and a system that shuts down fuel delivery to the engine in certain deceleration conditions. The grille shutters open or close based on engine coolant temperature and vehicle speed.

High-Voltage (HV) Battery Pack

Figure 2 - The eAssist system high-voltage (HV) battery is located in the trunk of the vehicle as shown on this 2012 Buick Regal.Unlike the BAS system, which used a 36-volt nickel-metal hydride battery, a 115-volt lithium-ion battery powers the eAssist system. The eAssist system HV battery pack is located in the trunk of the vehicle, directly behind the rear passenger seat (see Figure 2).

Figure 2 - The eAssist system high-voltage (HV) battery is located in the trunk of the vehicle as shown on this 2012 Buick Regal.Unlike the BAS system, which used a 36-volt nickel-metal hydride battery, a 115-volt lithium-ion battery powers the eAssist system. The eAssist system HV battery pack is located in the trunk of the vehicle, directly behind the rear passenger seat (see Figure 2).

The battery pack contains two battery sections connected in series that together provide 115-volts DC. The battery pack also contains some of the control modules and parts used by the eAssist system.

The battery pack has a metal tray that is fixed to the vehicle floor, which provides a mounting location for the HV parts. A cover is secured over the parts to prevent access without first disabling the HV system.

The HV battery sections are air-cooled. Each battery section case has an air inlet and an air outlet vent tube. An electric fan draws air through a vent located behind the rear seat through the battery case to cool the individual cells. In the event of a damaged or ruptured battery, any gases are vented to the outside of the vehicle.

High-Voltage Safety

Figure 3 - Always wear Class 0 electrically insulating rubber gloves with protective leather outer gloves when working on or near high-voltage parts.When working on or around vehicles with high-voltage systems, always follow the appropriate safety precautions. Read and follow the recommended service procedures for high-voltage systems and parts.

Figure 3 - Always wear Class 0 electrically insulating rubber gloves with protective leather outer gloves when working on or near high-voltage parts.When working on or around vehicles with high-voltage systems, always follow the appropriate safety precautions. Read and follow the recommended service procedures for high-voltage systems and parts.

Be sure to wear the appropriate personal protective equipment, which includes Class 0 insulated rubber gloves with leather outer gloves (see Figure 3). Always inspect the insulated gloves for any defects that might prevent the insulating properties, and do not wear them if they are damaged.

More information on high-voltage safety can be found in the Emergency Response Guides for the Buick LaCrosse, Regal, and Chevrolet Malibu eAssist equipped vehicles. These documents can be accessed for free at the www.gmstc.com website.

Damage Analysis and Repairs

GM service information states to not remove the battery pack cover when inspecting for damage. Inspect the battery pack assembly, cooling fan, air ducts, drive motor, and HV cables. Verify there are no cracks or dents, pinched, cut, or frayed cables, or other physical damage.

For repairs, some parts of the high-voltage system are serviceable. For example, the two lithium-ion battery sections are diagnosed and serviced as a single battery assembly. The individual battery sections are not serviced separately. The drive motor has two internal sensors that are not serviceable, the drive motor position sensor and the drive motor temperature sensor.

Refer to the service information for the proper procedures. Always refer to the service information for the appropriate disabling and safety procedures when working on any HV system parts.

High-Voltage Disabling

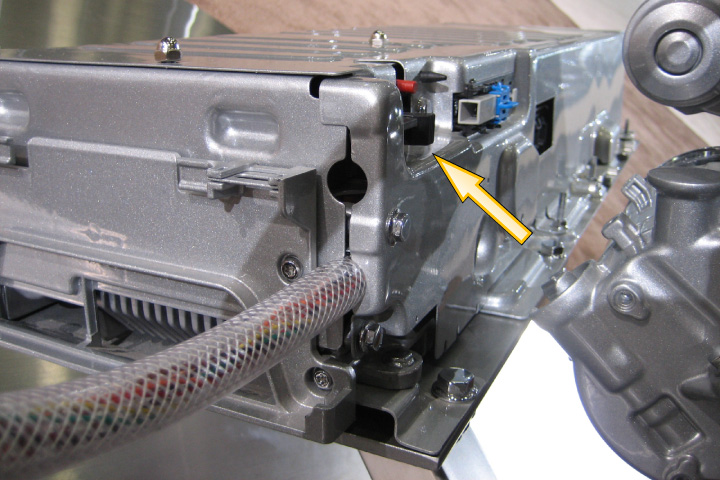

Figure 4 - Shown here is a display cutaway of the eAssist system high-voltage battery and drive motor.GM service information recommends waiting five minutes after turning the ignition OFF, to allow the HV capacitors to discharge before working on or around the HV system or parts (see Figure 4).

Figure 4 - Shown here is a display cutaway of the eAssist system high-voltage battery and drive motor.GM service information recommends waiting five minutes after turning the ignition OFF, to allow the HV capacitors to discharge before working on or around the HV system or parts (see Figure 4).

The HV battery pack, and the starter/generator each have an interlock switch located on the service access covers. The interlock will disable the high voltage when the starter/generator control module identifies that an high-voltage area has been accessed. When either cover is removed, the interlock loop is opened. The starter/generator control module will open the contactors to prevent contact with high-voltage.

The HV battery pack has a manual disconnect lever to allow disconnecting high-voltage from the eAssist system when performing service on the system (see Figure 5). The high-voltage manual disconnect lever and generator battery fuse are located in the battery energy control module wiring junction block assembly. This assembly is in a plastic tray that is secured to the top of the starter/generator control module.

High-Voltage Enabling

Figure 5 - The location of the manual disconnect switch on this eAssist system high voltage battery prop is shown here.When enabling the eAssist HV system, be sure that the manual disconnect lever, and the interconnect switch are in the closed position. Refer to the appropriate service information for the recommended procedures.

Figure 5 - The location of the manual disconnect switch on this eAssist system high voltage battery prop is shown here.When enabling the eAssist HV system, be sure that the manual disconnect lever, and the interconnect switch are in the closed position. Refer to the appropriate service information for the recommended procedures.

All fasteners for the HV parts must be tightened to the specified torque. Insufficient or excessive torque may result in malfunctions or damage to the parts or the system.

Conclusion

GM is introducing another version of electric-assist vehicle technology called eAssist beginning on some 2012 models. This system uses 115 volts to operate. It is important that anyone working on or around the high-voltage parts follows the appropriate safety precautions, and refers to the appropriate service information. Doing so will help to ensure a high level of safety when inspecting damage or making repairs on these vehicles.

This article first appeared in the October 11, 2012 edition of the I-CAR Advantage Online.

For additional GM information, check out the following pages:

Chevrolet OEM Information

GMC OEM Information

Buick OEM Information

Cadillac OEM Information

Additional I-CAR Collision Repair News you may find helpful:

Related I-CAR Courses

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

BMW Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Friday, 10 April 2020

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

SEMA 2025: Three-Dimensional Measuring Presentations

Thursday, 12 February 2026

I-CAR had numerous presentations at the 2025 SEMA show. Two presentations featured information about three-dimensional measuring of vehicles.

-

Body Repair Manual Symbols: Ford/Lincoln

Wednesday, 11 February 2026

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

-

I-CAR Repairers Realm: I-CAR Registered Apprenticeship Program - Coming Soon

Monday, 9 February 2026

I-CAR is having a discussion on the Registered Apprenticeship Program (RAP).

-

SEMA 2025: Lucid Motors Body Repair Team - The New Gravity SUV

Friday, 6 February 2026

I-CAR had numerous presentations at the 2025 SEMA show. One of these presentations focuses on Lucid Motors Gravity SUV repair information.

-

Calibration Research Tips: Blind Spot Indicator In Side Mirrors

Wednesday, 4 February 2026

While searching for information on advanced driver assistance systems (ADAS) on an OEM repair information site, you may come across unique calibration procedures or events. These events can vary by...

-

Bumper Cover Repair With ADAS: BMW/Mini - UPDATE

Tuesday, 3 February 2026

A simple bumper repair on a modern vehicle may not be as simple as it seems. New technologies like blind spot monitoring, adaptive cruise control, and other advanced driver assistance systems (ADAS)...

-

Hyundai/Genesis Part Replacement Without A Procedure

Thursday, 29 January 2026

We are often asked, “What do I do if there isn’t a procedure to replace a service part?” Let’s see what Hyundai/Genesis says.

-

Kia Part Replacement Without A Procedure

Thursday, 29 January 2026

We are often asked, “What do I do if there isn’t a procedure to replace a service part?” Let’s see what Kia says.

-

I-CAR Repairers Realm: New In 2026: I-CAR Academy - Now Available

Wednesday, 28 January 2026

I-CAR staff had a discussion on the I-CAR Academy.

-

Battery Backup And Low-Voltage Disconnect: Toyota/Lexus

Thursday, 22 January 2026

When an accident happens, how will you call for help? Maybe the telematics system, equipped with a backup battery, could automatically do this, even if the main power is cut off. What are the repair...

- 2026

- February 2026 (6)

- January 2026 (11)

- 2025

- December 2025 (8)

- November 2025 (11)

- October 2025 (13)

- September 2025 (11)

- August 2025 (12)

- July 2025 (11)

- June 2025 (11)

- May 2025 (11)

- April 2025 (13)

- March 2025 (12)

- February 2025 (11)

- January 2025 (12)

- 2024

- December 2024 (8)

- November 2024 (10)

- October 2024 (13)

- September 2024 (10)

- August 2024 (12)

- July 2024 (11)

- June 2024 (9)

- May 2024 (13)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (9)

- 2023

- December 2023 (8)

- November 2023 (12)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (11)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (11)

- October 2021 (13)

- September 2021 (14)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (11)

- April 2021 (14)

- March 2021 (20)

- February 2021 (14)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (14)

- May 2020 (14)

- April 2020 (19)

- March 2020 (12)

- February 2020 (13)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (19)

- April 2019 (20)

- March 2019 (20)

- February 2019 (18)

- January 2019 (17)

- 2018

- December 2018 (18)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (16)

- April 2018 (19)

- March 2018 (21)

- February 2018 (15)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (19)

- July 2017 (18)

- June 2017 (19)

- May 2017 (18)

- April 2017 (13)

- March 2017 (18)

- February 2017 (10)

- January 2017 (11)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (10)

- August 2016 (11)

- July 2016 (8)

- June 2016 (10)

- May 2016 (5)

- April 2016 (11)

- March 2016 (12)

- February 2016 (10)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (6)

- October 2015 (8)

- September 2015 (7)

- August 2015 (11)

- July 2015 (7)

- June 2015 (5)

- May 2015 (7)

- April 2015 (8)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (12)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (26)