The Importance Of Quality Control

Quality repairs are essential for customer safety and satisfaction, not to mention the time saved preventing rework and comebacks. Ensuring quality repairs are completed on each and every vehicle requires a commitment from the entire team. However, the manager is primarily responsible for making sure everyone is aware of the level of quality that is expected and verifying only high-quality repairs are being completed. This will require knowing how to identify high quality repairs and ensuring that poor repairs are corrected before the vehicle is returned to the customer, or before the vehicle is moved to the next phase of the repair process.

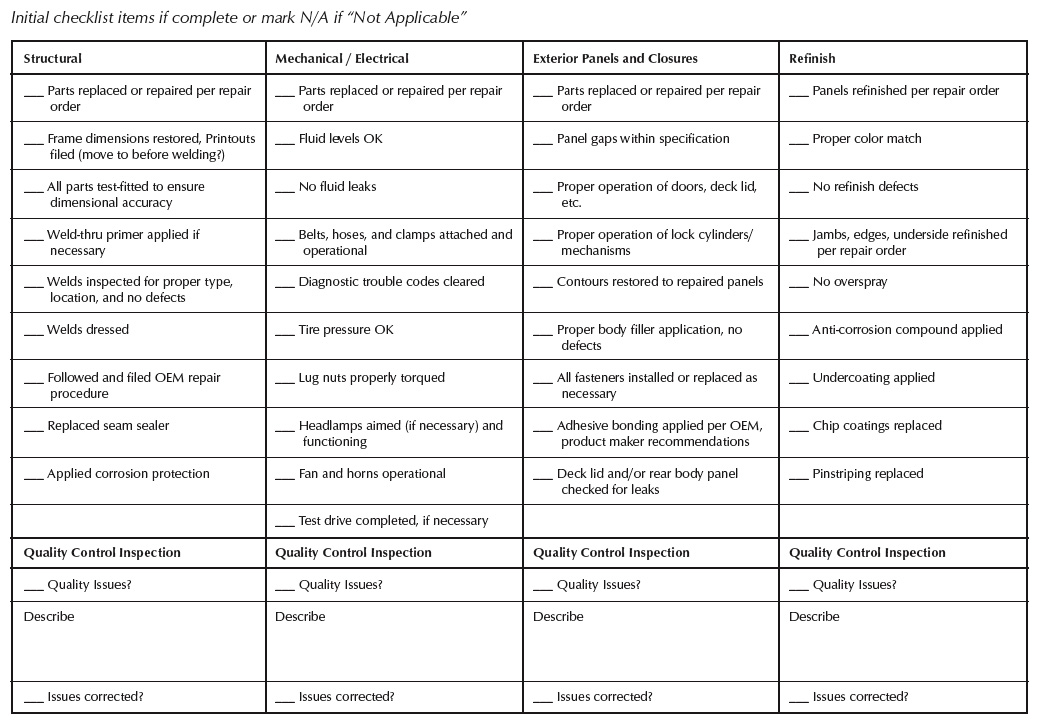

Inspection checklists can be used by both the technicians and managers to monitor and document the quality of the repairs on each vehicle. A checklist will provide the technician some guidance, or structure, to ensure each step necessary for a quality repair is completed. The manager, or designated quality control technician, can verify the tasks on the checklist were completed and mark the checklist accordingly.

Figure 1 - The bottom section on this sample inspection checklist provides an area to describe any quality issues, and an area that must be initialed by the manager to verify any issues were corrected.

Figure 1 - The bottom section on this sample inspection checklist provides an area to describe any quality issues, and an area that must be initialed by the manager to verify any issues were corrected.

Inspection Checklists

It's a good idea to use a checklist that's designed to be signed off by a manager or quality control technician before the vehicle is moved to the next department. This type of checklist may have an area to describe any quality issues identified during an inspection and an area to verify the issues were corrected (see Figure 1). This will help reduce compounding rework. For example, coatings may require removal and reapplication if quality issues are not identified before the coatings are applied in the first place.

Monitoring Technician Performance

Most managers don't have time to inspect each and every repair on each and every vehicle. However, it's important to monitor technician performance on a regular basis. This can be done by recording data from inspection checklists for periodic review.

One way to monitor technician performance is to review inspection checklists on a weekly basis and record any occurrences, which are repairs where corrective action is necessary. Patterns in performance will help identify strengths in technician performance and may help determine where training may be helpful.

Documentation

Taking photos of the repair areas may be another option to monitor and document technician performance. Some repairs may only be monitored by reviewing specification sheets, such as for measuring, wheel alignment, and welding equipment. However, this may also require some in-process monitoring to ensure the technician is using the equipment properly.

Conclusion

Monitoring technician performance is essential for ensuring quality repairs are being made on all vehicles. Tools that can be used to assist with this task may include checklists and spreadsheet formulas designed to record inspection data and display the information on an easy-to-read chart.

This article first appeared in the September 7, 2010 edition of the I-CAR Advantage Online.

Additional I-CAR Collision Repair News you may find helpful:

Related I-CAR Courses

Article validated in 2025

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

BMW Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Friday, 10 April 2020

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

Your 2025 Favorites: Top Articles

Friday, 16 January 2026

As 2026 rolls in, we can reflect back on what the previous year had to offer. Let's take a look at some of the collision industry information you've been most interested in from this past year....

-

App-Based Connected Services Considerations: Toyota/Lexus

Thursday, 15 January 2026

Have you had the experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and may...

-

Digital Key Considerations: Toyota/Lexus

Thursday, 15 January 2026

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

-

Nissan/INFINITI Position Statements: Advanced Driver Assistance System Components

Thursday, 8 January 2026

Nissan/INFINITI released position statements on the use of salvaged, aftermarket, and "secondary-market" advanced driver assistance systems (ADAS) components.

-

I-CAR Repairers Realm: RTS 2025 Year In Review - Now Available

Tuesday, 6 January 2026

I-CAR had a discussion on the Repairability Technical Support (RTS) 2025 year in review.

-

Ford On Target 2025: Volume 4

Monday, 5 January 2026

Ford has released the fourth installment of their On Target publication for 2025.

-

Structural Sectioning Procedures: Ford/Lincoln - UPDATE

Friday, 19 December 2025

Ask I-CAR receives many technical inquiries referring to sectioning. The collision repair industry wants to know where can you section, does the OEM have a sectioning procedure, and where can I find the...

-

Body Repair Manual Symbols: Hyundai

Wednesday, 17 December 2025

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

-

Body Repair Manual Symbols: Genesis

Wednesday, 17 December 2025

While looking at repair procedures in a body repair manual (BRM) you may notice that symbols are used to indicate specific operations or parts to be used during the repair process. Most BRMs provide a...

-

App-Based Connected Services Considerations: BMW

Wednesday, 10 December 2025

Have you had an experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and...

- 2026

- January 2026 (6)

- 2025

- December 2025 (8)

- November 2025 (11)

- October 2025 (13)

- September 2025 (11)

- August 2025 (12)

- July 2025 (11)

- June 2025 (11)

- May 2025 (11)

- April 2025 (13)

- March 2025 (12)

- February 2025 (11)

- January 2025 (12)

- 2024

- December 2024 (8)

- November 2024 (10)

- October 2024 (13)

- September 2024 (10)

- August 2024 (12)

- July 2024 (11)

- June 2024 (9)

- May 2024 (13)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (9)

- 2023

- December 2023 (8)

- November 2023 (12)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (11)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (11)

- October 2021 (13)

- September 2021 (14)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (11)

- April 2021 (14)

- March 2021 (20)

- February 2021 (14)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (14)

- May 2020 (14)

- April 2020 (19)

- March 2020 (12)

- February 2020 (13)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (19)

- April 2019 (20)

- March 2019 (20)

- February 2019 (18)

- January 2019 (17)

- 2018

- December 2018 (18)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (17)

- April 2018 (19)

- March 2018 (21)

- February 2018 (15)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (19)

- July 2017 (18)

- June 2017 (19)

- May 2017 (18)

- April 2017 (13)

- March 2017 (18)

- February 2017 (10)

- January 2017 (11)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (10)

- August 2016 (11)

- July 2016 (8)

- June 2016 (10)

- May 2016 (5)

- April 2016 (11)

- March 2016 (12)

- February 2016 (10)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (6)

- October 2015 (8)

- September 2015 (7)

- August 2015 (11)

- July 2015 (7)

- June 2015 (5)

- May 2015 (7)

- April 2015 (8)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (12)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (26)