OEM Technical Information Matrix - Volvo Update

- Posted on 09 July 2014

The OEM Technical Information Matrix has been updated to include Volvo information. The corresponding, Collision Repair Information Availability chart has also been updated on the Volvo-specific OEM Information page.

2015 Ford Mustang to Employ Extensive Use of HSS & UHSS

- Posted on 08 July 2014

Earlier this year, at Great Designs in Steel 2014, Ford shared details about the construction of the 2015 Ford Mustang. The 2015 Mustang will use a variety of different steels, from mild to ultra-high-strength (UHSS), throughout the vehicle structure.

To Each Their Own - OEM-Specific Pages

- Posted on 03 July 2014

More great things have been added with the launch of the new website. Each OEM, or vehicle maker, now has their own web page. You are able to access an OEM-specific page by clicking on their emblem. There are a variety of types of information available for each OEM. The icons will link you the following OEM-specific types of information:

Working With Boron-Alloyed Steel - Removal (Cutoff Wheel)

- Posted on 23 June 2014

When attempting to cut boron-alloyed steel using a cutoff wheel, you may question whether you will even be able to cut the part or just be using up discs?

Is There a Procedure for Disassembling a Service Assembly?

- Posted on 19 June 2014

The fourth column in the OEM Technical Information Matrix, Partial Service Part/Assembly Replacement Procedures at Factory Seams, can get a little tricky without further clarification. For the most part, this is a column that I-CAR is still researching published OEM information to get the answers to. The question is: Does the vehicle maker have procedures for replacing a partial service part or assembly at factory seams?

Working With Boron-Alloyed Steel - Removal (Air Chisel)

- Posted on 17 June 2014

Ever hear how an air chisel is for mechanics and nothing more than a crude tool for cutting a hole in a part to gain access? Would you ever use it to remove an exterior body panel from a reinforcement?

What's A Mitsubishi Rear End Crossmember?

- Posted on 13 June 2014

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts. All of the different names can be confusing, especially when repairing a variety of vehicle makes and models.

Didn't I Print That?

- Posted on 12 June 2014

Have you ever printed a repair procedure only to find out that later on when you went to reference the information, it wasn't there? If so, most likely you discovered it the day after your short-term subscription expired, or it was for a procedure that was particularly difficult to find in the manual. You may have wondered if you did something wrong of if the procedure even exists.

Working With Boron-Alloyed Steel - Removal (Belt Sander)

- Posted on 09 June 2014

How do you remove spot welds on something that is harder than a drill bit? Well you could always use a file belt sander.

Working With Boron-Alloyed Steel - Removal (Drilling)

- Posted on 05 June 2014

To drill or not to drill, that is the question or more appropriately "how do I drill boron-alloyed steel so I don't keep going through drill bits?" Many of us have asked ourselves this when working with boron-alloyed steel or ultra-high-strength steel (UHSS).

Product Maker Information On OEM Technical Information Matrix

- Posted on 03 June 2014

There are an increasing number of materials being used in vehicles to help make them safer and create a quieter passenger compartment. Foam fillers, seam sealers, and adhesives often help accomplish this. It is impossible to see the location of all of these materials simply by looking at the outside of the vehicle. Not to mention, when you look at a product maker's catalog, there are many different options for replacement materials. So the question is: where do I find this information to repair the vehicle properly?

MIG Brazing What Is It, Why Should I Use It?

- Posted on 02 June 2014

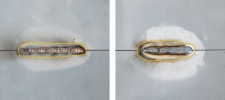

Why MIG Brazing?

It is widely known that GMA welded; fully galvanized steel will lose some of its properties, including corrosion protection, due to the heat created during welding. OEMs are starting to counter this problem by using MIG brazing along with "stitch" and "skip" methods to control the heat. However, MIG brazing should only be done in areas specified by an OEM procedure. With MIG brazing, the lower heat input burns away a minimal amount of the zinc corrosion protection (galvanizing) adjacent to the weld (see Figure 1).

What's A Mercedes-Benz Outer Side Longitudinal Member?

- Posted on 30 May 2014

When it comes to repair information, vehicle makers use a wide variety of terminology for replacement parts. All of the different names can be confusing, especially when repairing a variety of vehicle makes and models.

Do I Really Have To Follow Vehicle Maker Recommendations?

- Posted on 29 May 2014

It's just a recommendation, if they wanted me to follow it, they would call it a requirement, right? Wrong!

Working With Boron-Alloyed Steel - Identification

- Posted on 26 May 2014

Knowing whether or not a part is made of boron-alloyed steel is important for repairs and replacement. OEM repair information is the best source to identify if a part is UHSS.decisions. The location of the part can be used to determine if the part is likely to be an ultra-high-strength steel (UHSS) part. However, part location is not definitive, the part could be boron-alloyed steel or it could be a part that is below 600MPa steel. The location will help to prompt further research into straightening, sectioning, or replacing at factory seams. Steel identification may also help determine removal and attachment methods.

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Position Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published position statement on pre-repair and post-repair scanning? We have compiled a list of most of the position statements on the...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

Typical Calibration Requirements For Blind Spot Sensors

Wednesday, 19 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

Honda Has Released The 2024 Prologue Body Repair News

Wednesday, 15 May 2024

Honda has released a Body Repair News bulletin for the 2024 Honda Prologue. This document provides relevant information at a glance for this new model which was co-developed with General Motors (GM).

-

Acura Has Released The New 2024 ZDX Body Repair News

Wednesday, 15 May 2024

Acura has released a Body Repair News bulletin for the 2024 Acura ZDX. This document provides relevant information at a glance for this new model which was co-developed with General Motors (GM).

-

GM Repair Insights: Spring 2024

Monday, 13 May 2024

The spring edition of General Motors (GM) Repair Insights magazine is now available.

-

OEM Linking Pin: Kia Outer Uniside Sectioning

Friday, 10 May 2024

As part of the I-CAR Repairability Technical Support (RTS) OEM linking pin activity, we are helping to connect the collision repair industry to the vehicle makers. We’ve had technical inquiries that...

-

Calibration Research Tips: Nissan/INFINITI - Bumper Cover Replaced With Sonar Sensor Holder

Thursday, 9 May 2024

While searching for information on advanced driver assistance systems (ADAS) on an OEM repair information site, you may come across unique calibration procedures or events. These events can vary by...

-

I-CAR Just In Time: Lineman’s Glove Testing

Tuesday, 7 May 2024

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

-

OEM Emergency Response Guides: BMW/Mini

Thursday, 2 May 2024

Are you looking for OEM emergency response guides (ERGs)? The Repairability Technical Support (RTS) team has located these guides and either houses them on the RTS website, provides links to...

-

I-CAR Ford Mach-E Collision Repair And Electromechanical Repair Courses

Wednesday, 1 May 2024

I-CAR has developed courses for the Ford Mustang Mach-E, a general collision repair overview and a course that covers electromechanical repair.

-

I-CAR Repairers Realm: Controlling Static During Refinishing - Now Available

Tuesday, 30 April 2024

I-CAR had a discussion on controlling static during refinishing.

-

Film Thickness Gauge For Plastic Parts - Is It Worth The Investment?

Friday, 26 April 2024

Film thickness gauges continue to be a valuable tool in the collision industry. Most shops have gauges that work with both ferrous and non-ferrous substrates. So, should shops invest in a film...

- 2024

- May 2024 (8)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (10)

- 2023

- December 2023 (8)

- November 2023 (13)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (12)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (12)

- October 2021 (13)

- September 2021 (15)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (14)

- April 2021 (14)

- March 2021 (21)

- February 2021 (15)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (16)

- May 2020 (14)

- April 2020 (20)

- March 2020 (12)

- February 2020 (14)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (21)

- May 2019 (19)

- April 2019 (20)

- March 2019 (21)

- February 2019 (21)

- January 2019 (18)

- 2018

- December 2018 (19)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (17)

- April 2018 (19)

- March 2018 (22)

- February 2018 (16)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (20)

- July 2017 (18)

- June 2017 (23)

- May 2017 (20)

- April 2017 (14)

- March 2017 (18)

- February 2017 (11)

- January 2017 (13)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (11)

- August 2016 (11)

- July 2016 (8)

- June 2016 (13)

- May 2016 (10)

- April 2016 (11)

- March 2016 (12)

- February 2016 (11)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (8)

- October 2015 (9)

- September 2015 (7)

- August 2015 (11)

- July 2015 (10)

- June 2015 (8)

- May 2015 (8)

- April 2015 (9)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (14)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (27)