Challenges Ahead: Keeping Pace With Rapid Advances In Collision Repair

As the automotive industry moves deeper into the mobility arena, it also enters a more challenging realm for the collision repair industry.

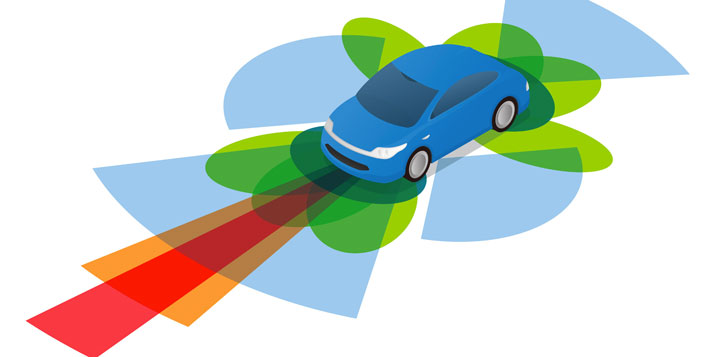

The wide array of advanced driver assistance systems (ADAS) that provide active safety measures for vehicle occupants are powered by an electronic communication network that requires near-perfect accuracy when repaired after a collision.

Features such as lane-keep assist, collision mitigation, blind spot detection, adaptive cruise control, and automatic braking contain a network of wiring and control modules that work with cameras, sensors, radar and LIDAR to detect and calculate speed and distance in fractions of a second and alert the driver about potential threats. Errors in repairing any component of these highly sensitive electronic components could result in catastrophe.

The growth in electric vehicle (EV) sales translates to yet another electronic system that collision repair professionals will be required to repair.

A system pre-scan is being done to aid in the repair plan process.

A system pre-scan is being done to aid in the repair plan process.

The European Commission has declared 2025 as the target year when all new vehicles sold in Europe will be electric and China has set a 40 percent EV goal for 2030. Although the U.S. has yet to set a target for EV sales, the global nature of the automotive industry will induce U.S. OEMs to increase EV production to meet the standards set in countries where they sell vehicles.

Battery packs for EVs bring different electronic systems into the collision repair shop, as well as the need to ensure proper thermal management.

As ADAS continues to gain in technological sophistication and EVs continue their rapid growth, collision repair shops will need to provide ongoing training to help keep their Technicians up-to-speed with the continuous, fast paced changes to these complex vehicle systems.

ADAS control modules rely heavily on external cameras and sensors positioned around the vehicle to interpret data, calculate distance and relay information to driver warning systems.

Special 360 camera calibration mats for the new Ford F-150.

Special 360 camera calibration mats for the new Ford F-150.

Both cameras and sensors use radar and LIDAR to detect the presence of a potential threat, the distance from it and the speed to impact. For the collision repair specialist, this means understanding how these systems work individually, as well as together, to provide active safety benefits.

The best resource for understanding how the components of ADAS integrate into a system is vehicle maker repair information.

Repair information often provides a systems overview, along with details on how to work with specific aspects of the ADAS components used in that particular system. Technicians will also have to rely on the information gathered by scan tools.

During the blueprinting process, a scan tool can be used to identify damage that the eye cannot detect, especially hidden damage in the vehicle’s electronic communication network.

Similar to three-dimensional (3D) measuring being used to identify damage to the vehicle structure, a pre-repair scan can become the foundation for repairs required for ADAS and other electronic systems. It facilitates the discovery of damage throughout the vehicle and serves as the blueprint that guides the repair plan.

Forward-facing camera calibration set-up on a Hondar CR-V.

Forward-facing camera calibration set-up on a Hondar CR-V.

To complicate matters further, collision repair professionals must select the right scan tool for each evaluation from an array of scan tools with different capabilities designed to detect damage in various ways and at different levels.

For example, there are basic code readers, aftermarket scan tools and OEM-specific scan tools. It’s important to understand how each tool works. This is where shop standard operating procedures (SOPs) come into play.

It’s highly beneficial for collision repair shops to utilize SOPs for proper diagnostics, including: retrieving, recording and assessing diagnostic trouble codes (DTCs); performing calibration procedures; and completing post-repair scanning and system verification processes.

SOPs help streamline the approach to each vehicle repair, create efficiencies throughout the repair process and facilitate a complete, safe and quality repair.

Special targets for the forward-facing camera calibration on a Honda CR-V.

Special targets for the forward-facing camera calibration on a Honda CR-V.

Calibration and aiming, or both, is an essential step in repairing ADAS. Because ADAS operates using highly sensitive cameras and sensors, proper calibration / aiming is imperative for these interdependent systems to work with high degrees of accuracy.

I-CAR, a not-for-profit organization, has developed specific courses to enable collision repair specialists to conduct a complete damage analysis for ADAS as well as the calibration requirements to fix them.

As simple as it sounds, the first step is to identify the specific type of ADAS that needs repair. From there, our best practices for repairing complex ADAS include:

- Using a factory scan tool

- Identify all modules and build data

- Will have current model year

- Can perform all program / scan / calibration / initializations

- Using an aftermarket scan tool

- Identifies most modules

- May not have coverage of most current model year

- May not be able to identify / communicate with all modules

- OEMs may not test or approve aftermarket scan tools

- Can perform many program / scan / calibration / initialization procedures

- A robust scan tool can do most program / scan / calibration / initialization

Advanced driver assistance systems (ADAS) rely heavily on external cameras and sensors to interpret data, calculate distance and relay information to driver warning systems.

Advanced driver assistance systems (ADAS) rely heavily on external cameras and sensors to interpret data, calculate distance and relay information to driver warning systems.

- Using OEM repair information and VIN build data

- Not all OEMS have build data in non-dealership information

- Not all OEM build data terms mirror repair information terms

- Some have a sales designation for an ADAS that does not match the name in the repair information

- Identify systems updates from pre-repair scan

- Use Diagnostic Trouble Code (DTC) information

- Flow charts

- Part location diagrams

- Physical damage to systems / parts / wires / mounting areas

- Modules that are present, but unresponsive

- Identify calibration requirements

- I-CAR’s Repairability Technical Support (RTS) portal calibration requirement search

- Need OEM repair information to perform procedures

- OEM information for procedures

- Special tools / targets / scan tool requirements / drive cycle requirements

- Some parts may require in-process calibration to verify the system will be calibrated when repairs are completed

- If mounting location is damaged / disturbed

- Prepare for post-repair calibration and post-repair scan

I-CAR has also published, with the help of inter-industry subject matter experts, information on considerations for ADAS diagnosis and repair.

Calibration set-up for the blind spot sensors on a Lexus RC 300.

Calibration set-up for the blind spot sensors on a Lexus RC 300.

EVs and hybrid electric vehicles (HEVs) bring additional challenges to the collision repair facility. When repairing EVs and HEVs, it’s imperative to follow OEM information. Properly disabling these vehicles’ high-voltage batteries is critical for personal and vehicle safety. OEM procedures include disabling the high-voltage battery system before repairs begin, precautions for moving disabled vehicles throughout the repair facility and refinishing considerations.

As the automotive industry continues to drive toward mobility and autonomy, new technologies will be developed to support ADAS that are even more advanced than those found on today’s new vehicles. I-CAR is committed to keeping pace with these innovative developments from the collision repair side by continually adapting our course offerings to give collision repair Technicians the knowledge and skills they need to perform complete, safe and quality repairs. Our organization will continue to build tools and articles, while closing gaps in available collision repair information, via the I-CAR Repairability Technical Support (RTS) initiative.

Reprinted with permission from Fixed Ops Magazine September / October 2018 issue.

Additional I-CAR Collision Repair News you may find helpful:

Related I-CAR Courses

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Position Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published position statement on pre-repair and post-repair scanning? We have compiled a list of most of the position statements on the...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

Typical Calibration Requirements For Blind Spot Sensors

Wednesday, 19 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

Calibration Research Tips: Nissan/INFINITI - Bumper Cover Replaced With Sonar Sensor Holder

Thursday, 9 May 2024

While searching for information on advanced driver assistance systems (ADAS) on an OEM repair information site, you may come across unique calibration procedures or events. These events can vary by...

-

I-CAR Just In Time: Lineman’s Glove Testing

Tuesday, 7 May 2024

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

-

OEM Emergency Response Guides: BMW/Mini

Thursday, 2 May 2024

Are you looking for OEM emergency response guides (ERGs)? The Repairability Technical Support (RTS) team has located these guides and either houses them on the RTS website, provides links to...

-

I-CAR Ford Mach-E Collision Repair And Electromechanical Repair Courses

Wednesday, 1 May 2024

I-CAR has developed courses for the Ford Mustang Mach-E, a general collision repair overview and a course that covers electromechanical repair.

-

I-CAR Repairers Realm: Controlling Static During Refinishing - Now Available

Tuesday, 30 April 2024

I-CAR had a discussion on controlling static during refinishing.

-

Film Thickness Gauge For Plastic Parts - Is It Worth The Investment?

Friday, 26 April 2024

Film thickness gauges continue to be a valuable tool in the collision industry. Most shops have gauges that work with both ferrous and non-ferrous substrates. So, should shops invest in a film...

-

Body Shop Business: EV Intake Process

Wednesday, 24 April 2024

Body Shop Business has released an article highlighting the importance of the electric vehicle (EV) intake process.

-

Repairer Driven News: Matte Clearcoat Challenges

Monday, 22 April 2024

Repairer Driven News (RDN) has released an article highlighting the challenges of matte and semi-gloss clearcoat.

-

I-CAR Just In Time: EV Repair Tips

Wednesday, 17 April 2024

Sometimes seeing is understanding, that’s why I-CAR's technical team created the Just in Time video series to guide you through a variety of collision repair topics from ADAS and EVs to repair tips...

-

I-CAR RTS App

Monday, 15 April 2024

Looking for another tool for your toolbox? An informational guide at your fingertips? Well, the I-CAR Repairability Technical Support (RTS) app is what you are looking for!

- 2024

- May 2024 (4)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (10)

- 2023

- December 2023 (8)

- November 2023 (13)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (12)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (12)

- October 2021 (13)

- September 2021 (15)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (14)

- April 2021 (14)

- March 2021 (21)

- February 2021 (15)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (16)

- May 2020 (14)

- April 2020 (20)

- March 2020 (12)

- February 2020 (14)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (21)

- May 2019 (19)

- April 2019 (20)

- March 2019 (21)

- February 2019 (21)

- January 2019 (18)

- 2018

- December 2018 (19)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (17)

- April 2018 (19)

- March 2018 (22)

- February 2018 (16)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (20)

- July 2017 (18)

- June 2017 (23)

- May 2017 (20)

- April 2017 (14)

- March 2017 (18)

- February 2017 (11)

- January 2017 (13)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (11)

- August 2016 (11)

- July 2016 (8)

- June 2016 (13)

- May 2016 (10)

- April 2016 (11)

- March 2016 (12)

- February 2016 (11)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (8)

- October 2015 (9)

- September 2015 (7)

- August 2015 (11)

- July 2015 (10)

- June 2015 (8)

- May 2015 (8)

- April 2015 (9)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (14)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (27)