Bonding And Rivet Bonding Technology On Steel BMW Vehicle Parts

Figure 1 - This BMW 5 Series has several parts that need to be rivet bonded during repairs.

Figure 1 - This BMW 5 Series has several parts that need to be rivet bonded during repairs. As BMW Groups' vehicle construction technology advances, so does the repair process required to fix them properly. Conventional welding, which has been used primarily in BMW Groups' repair processes in the past, is slowly becoming the secondary method to bonding and rivet bonding technology. BMW currently recommends primarily using bonding and rivet bonding to replace exterior body panels, structural parts, and sectioning specific locations in conjunction with VIN-specific repair procedures. Changes in recommended repair procedures affect all current production models. This does not mean that all models, and all parts, are affected though. Consulting VIN-specific repair procedures should always be the first step in the repair process. The same is true for Mini and for Rolls-Royce vehicles (see Figure 1).

BMW Group has been recommending bonding and rivet bonding techniques to replace damaged aluminum parts for over a decade. The recommendation has now been brought to repairs on steel vehicles. The theory behind the repair of both aluminum and steel parts is similar, although the adhesives and preparation  Figure 2 - The repairs on this aluminum front end are similar to the repairs on steel vehicles.material used can vary by the repair situation and the materials being joined (see Figure 2).

Figure 2 - The repairs on this aluminum front end are similar to the repairs on steel vehicles.material used can vary by the repair situation and the materials being joined (see Figure 2).

Reasons for the Change

There are several reasons that BMW has made the transition from conventional welding and STRSW to bonding and rivet bonding. One of the main reasons is the use of heat-sensitive steel. With bonding and rivet bonding, there is no heat generated that would weaken the steel, allowing the steel to retain its strength.

Another reason for bonding and rivet bonding is the increased corrosion resistance of the repair joints. Corrosion protection is extremely important during repairs because BMW offers a 12-year corrosion warranty.

Repair Overview

The recommended BMW sectioning joint on outer body panels requires a pre-fabricated E-coated reinforcement plate, available from BMW, along with VIN-specific repair information. The sectioning joint locations are in a similar area as the previously recommended weld joint, but may have moved to accommodate the reinforcement plate. The reinforcement plate has studs built into the part. This requires notches to be placed into the existing part and the new part.

Special plastic lock nuts are used to hold the parts in position until the adhesive cures. If the joint calls for them, rivets, which may be special blind rivets or punch rivets (also called self-piercing rivets or SPRs), are then installed on mating flange areas where applicable. When the adhesive is cured, the studs on the reinforcement plate are removed and the surface is prepared for the application of the BMW-recommended epoxy metal filler.

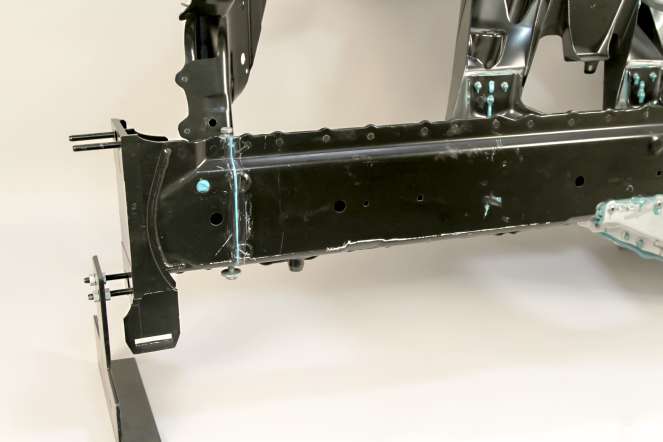

Figure 3 - The repair elements for aluminum repair that are shown are the same concept for repairs on steel rails.The sectioning procedure for a rail is similar to an outer body panel. The difference is this repair joint uses a repair element that fits into the rail. A bolt is inserted into the repair element. When the bolt is tightened down, the repair element expands against the inside of the rail, causing the adhesive to emerge. The bolt is removed once the rivets have been installed and the adhesive is cured (see Figure 3).

Figure 3 - The repair elements for aluminum repair that are shown are the same concept for repairs on steel rails.The sectioning procedure for a rail is similar to an outer body panel. The difference is this repair joint uses a repair element that fits into the rail. A bolt is inserted into the repair element. When the bolt is tightened down, the repair element expands against the inside of the rail, causing the adhesive to emerge. The bolt is removed once the rivets have been installed and the adhesive is cured (see Figure 3).

Still Some Welding

Bonding and rivet bonding does not replace all welding procedures for BMW. There are some areas that will still require welding to be done. These areas can only be identified with the correct repair information.

Tools and Equipment Availability

All of the tools and parts, including the reinforcement plates, repair elements, rivets, and adhesives needed to complete bonding and rivet bonding procedures for BMW are available to independent collision repair facilities. It is highly recommended, however, that before any repairs are attempted, the technician acquire training from BMW on the tools and techniques to correctly perform these repairs. It is also critical to have access to the most current and up-to-date repair procedures and sectioning locations from BMW.

Conclusion

BMW recommends primarily using adhesive bonding and rivet bonding to replace exterior body panels, frame rails, and when sectioning. The repairs are vehicle specific and require special tools, equipment, and procedures. BMW recommends specific training before doing these repairs, and having access to their specific repair information.

The recommended change in repair procedures from BMW is just one of the many examples of the challenges that collision repairers face on today's HSS and UHSS vehicles. While traditional repair methods are still used on these vehicles, how and where those repair methods are used is constantly changing.

This article first appeared in the April 26, 2012 edition of the I-CAR Advantage Online.

Related I-CAR Courses

-

Toyota/Lexus/Scion Position Statement: Pre- and Post-Repair System Scanning

Thursday, 28 July 2016

As the industry continues to ask if pre- and post-repair system scanning is necessary, Toyota/Lexus/Scion provides their answer.

-

Pre- and Post-Repair System Scanning Statements

Wednesday, 9 January 2019

Are you wondering if a particular OEM or organization has a published statement on pre-repair and post-repair scanning? We have compiled a list of most of the statements on the subject, so you can...

-

ADAS, Calibration, And Scanning Article Hotspot

Monday, 14 January 2019

Since advanced driver assistance systems (ADAS), scanning, and calibration first started becoming relevant, members of the collision repair industry have required as much knowledge as possible on...

-

BMW Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Friday, 10 April 2020

BMW has released a position statement related to pre- and post-repair system scanning. The statement applies to All vehicles equipped with on board diagnostics II (OBD II).

-

Honda/Acura Position Statement: Pre- and Post-Repair System Scanning - UPDATE

Wednesday, 22 May 2019

Honda /Acura has updated their position statement on pre- and post-repair scanning to give more clarification on what is expected for scanning.

-

Quickly Identifying Outer Quarter Panels w/Rolled Hem Flanges

Monday, 5 March 2018

The I-CAR best practice article, Recycled Outer Quarter Panels w/Rolled Hem Flanges has gotten a lot of interest from the collision repair industry. It’s important to know which vehicles are...

-

General Motors Position Statement: Pre- and Post-Repair System Scanning

Friday, 21 October 2016

As the industry continues to ask, are pre- and post-repair scans necessary, General Motors provides their answer.

-

Restraints Wiring Repairs

Monday, 23 May 2016

Over the past few months, we've been sharing OEM position statements on restraints wiring repairs. Now we're bringing them all together in one place for easy reference.

-

FCA/Stellantis Position Statement: Pre- and Post-Repair System Scanning

Thursday, 9 June 2016

FCA/Stellantis has released a position statement related to pre- and post-repair system scanning.

-

Typical Calibration Requirements For Forward Radar Sensors

Wednesday, 12 October 2016

Technicians should be aware of what’s required to keep advanced driver assistance systems (ADAS) running safely after a collision. Whether that be aiming a camera, which can cause a system to not...

-

Hyundai/Genesis Part Replacement Without A Procedure

Thursday, 29 January 2026

We are often asked, “What do I do if there isn’t a procedure to replace a service part?” Let’s see what Hyundai/Genesis says.

-

Kia Part Replacement Without A Procedure

Thursday, 29 January 2026

We are often asked, “What do I do if there isn’t a procedure to replace a service part?” Let’s see what Kia says.

-

I-CAR Repairers Realm: New In 2026: I-CAR Academy - Now Available

Wednesday, 28 January 2026

I-CAR staff had a discussion on the I-CAR Academy.

-

Battery Backup And Low-Voltage Disconnect: Toyota/Lexus

Thursday, 22 January 2026

When an accident happens, how will you call for help? Maybe the telematics system, equipped with a backup battery, could automatically do this, even if the main power is cut off. What are the repair...

-

Your 2025 Favorites: Top 20 Sectioning and Partial Part Vehicles

Wednesday, 21 January 2026

Now that the new year is underway, let’s take a look at your 2025 favorite vehicles in the OEM Partial Part Replacement Search.

-

Your 2025 Favorites: Top Articles

Friday, 16 January 2026

As 2026 rolls in, we can reflect back on what the previous year had to offer. Let's take a look at some of the collision industry information you've been most interested in from this past year....

-

App-Based Connected Services Considerations: Toyota/Lexus

Thursday, 15 January 2026

Have you had the experience where the vehicle notified the owner that it was being moved while it was in your repair facility? App-based connected services are available from many vehicle makers and may...

-

Digital Key Considerations: Toyota/Lexus

Thursday, 15 January 2026

The intermingling of technology and automobiles continues, with digital key offerings from most vehicle makers. Digital keys utilize smartphone technology to expand vehicle access and owner...

-

Nissan/INFINITI Position Statements: Advanced Driver Assistance System Components

Thursday, 8 January 2026

Nissan/INFINITI released position statements on the use of salvaged, aftermarket, and "secondary-market" advanced driver assistance systems (ADAS) components.

-

I-CAR Repairers Realm: RTS 2025 Year In Review - Now Available

Tuesday, 6 January 2026

I-CAR had a discussion on the Repairability Technical Support (RTS) 2025 year in review.

- 2026

- January 2026 (11)

- 2025

- December 2025 (8)

- November 2025 (11)

- October 2025 (13)

- September 2025 (11)

- August 2025 (12)

- July 2025 (11)

- June 2025 (11)

- May 2025 (11)

- April 2025 (13)

- March 2025 (12)

- February 2025 (11)

- January 2025 (12)

- 2024

- December 2024 (8)

- November 2024 (10)

- October 2024 (13)

- September 2024 (10)

- August 2024 (12)

- July 2024 (11)

- June 2024 (9)

- May 2024 (13)

- April 2024 (12)

- March 2024 (12)

- February 2024 (12)

- January 2024 (9)

- 2023

- December 2023 (8)

- November 2023 (12)

- October 2023 (11)

- September 2023 (11)

- August 2023 (12)

- July 2023 (9)

- June 2023 (11)

- May 2023 (12)

- April 2023 (11)

- March 2023 (12)

- February 2023 (10)

- January 2023 (11)

- 2022

- December 2022 (11)

- November 2022 (12)

- October 2022 (11)

- September 2022 (13)

- August 2022 (11)

- July 2022 (10)

- June 2022 (13)

- May 2022 (11)

- April 2022 (12)

- March 2022 (10)

- February 2022 (11)

- January 2022 (13)

- 2021

- December 2021 (13)

- November 2021 (11)

- October 2021 (13)

- September 2021 (14)

- August 2021 (12)

- July 2021 (15)

- June 2021 (17)

- May 2021 (11)

- April 2021 (14)

- March 2021 (20)

- February 2021 (14)

- January 2021 (14)

- 2020

- December 2020 (13)

- November 2020 (17)

- October 2020 (12)

- September 2020 (14)

- August 2020 (11)

- July 2020 (18)

- June 2020 (14)

- May 2020 (14)

- April 2020 (19)

- March 2020 (12)

- February 2020 (13)

- January 2020 (14)

- 2019

- December 2019 (13)

- November 2019 (19)

- October 2019 (25)

- September 2019 (20)

- August 2019 (22)

- July 2019 (23)

- June 2019 (20)

- May 2019 (19)

- April 2019 (20)

- March 2019 (20)

- February 2019 (18)

- January 2019 (17)

- 2018

- December 2018 (18)

- November 2018 (19)

- October 2018 (17)

- September 2018 (16)

- August 2018 (21)

- July 2018 (20)

- June 2018 (21)

- May 2018 (17)

- April 2018 (19)

- March 2018 (21)

- February 2018 (15)

- January 2018 (20)

- 2017

- December 2017 (13)

- November 2017 (15)

- October 2017 (19)

- September 2017 (20)

- August 2017 (19)

- July 2017 (18)

- June 2017 (19)

- May 2017 (18)

- April 2017 (13)

- March 2017 (18)

- February 2017 (10)

- January 2017 (11)

- 2016

- December 2016 (9)

- November 2016 (14)

- October 2016 (21)

- September 2016 (10)

- August 2016 (11)

- July 2016 (8)

- June 2016 (10)

- May 2016 (5)

- April 2016 (11)

- March 2016 (12)

- February 2016 (10)

- January 2016 (8)

- 2015

- December 2015 (9)

- November 2015 (6)

- October 2015 (8)

- September 2015 (7)

- August 2015 (11)

- July 2015 (7)

- June 2015 (5)

- May 2015 (7)

- April 2015 (8)

- March 2015 (8)

- February 2015 (9)

- January 2015 (10)

- 2014

- December 2014 (12)

- November 2014 (7)

- October 2014 (11)

- September 2014 (10)

- August 2014 (9)

- July 2014 (12)

- June 2014 (9)

- May 2014 (12)

- April 2014 (9)

- March 2014 (6)

- February 2014 (1)

- January 2014 (26)